Moringa seed is the seed of Moringa tree. Moringa oleifera is a perennial tropical, Yunnan Moringa seed and subtropical deciduous tree. It belongs to the genus Moringa, belonging to the family Moringaceae. It originated in India and has a history of more than 1000 years. It has been planted in tropical and subtropical regions of Africa and the world.

The leaves, flowers, tender pods and seeds of Moringa oleifera are edible directly; The powder ground from its tender roots is one of the raw materials for making curry powder. The oil extracted from Moringa seeds is edible oil. Since ancient times, pungent trees have provided daily nutrition for Indian vegetarians and are easy to cultivate. Therefore, the promotion of pungent trees in Africa has been regarded as an aid project by the United Nations to solve the food shortage in Africa.

The technology of making oil from Moringa oleifera seed is as follows

For the extraction and processing of Moringa oleifera seed oil, we recommend that pure physical cold pressing or screw pressing can be used to process Moringa oleifera seed oil. The cold pressing process can greatly protect the nutritional components of the oil from any damage, and the investment cost is relatively small. Especially suitable for small oil and small output customers.

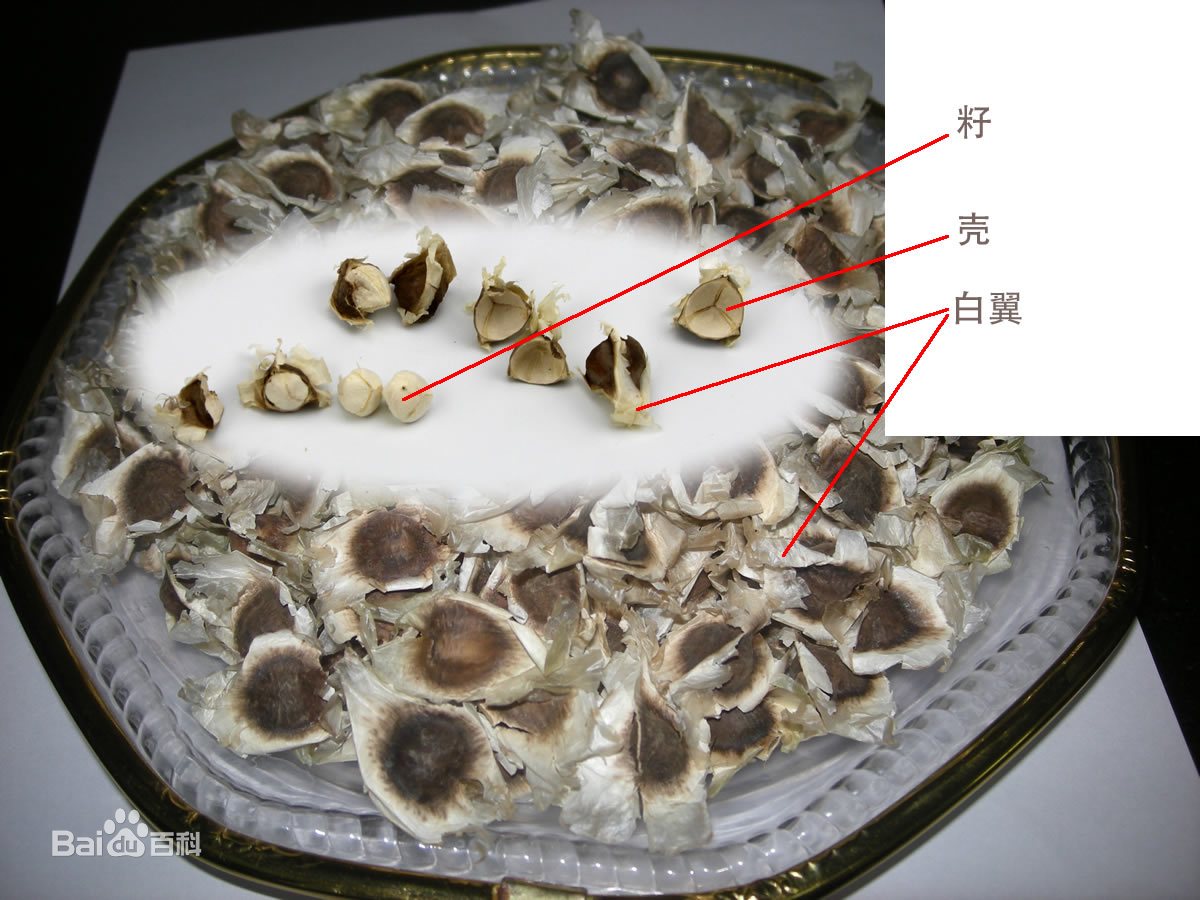

Because there is a hard shell on the outside of Moringa oleifera seeds, we need to shell them before pressing. After screening to remove impurities, stone machine to remove stone dust and other processes, processed Moringa seed is selected and crushed into fine powder by crusher. Then it is sent to cold press equipment. Hydraulic press and screw press can be selected to cold press crude oil at low temperature. After effective refining, high-quality seabuckthorn seed oil can be obtained.

Refined oil production process:

Degumming: colloidal impurities in crude oil, mainly phosphorus. The existence of colloidal substances, such as phospholipids, not only reduces the quality of oil, but also promotes the transition emulsification between oil and lye in the process of alkali refining and deacidification, increases the difficulty of separation of Gleditsia sinensis, and aggravates the loss of neutral oil. Therefore, it should be removed first. The temperature of water is slightly higher than that of oil. If necessary, 0.2% - 0.3% salt can improve the hydration effect. Water adding operation is the most important stage of hydration. It is necessary to carefully control the amount of water added, the temperature of water and oil, the speed of mixing and adding water, etc. When hydration, always use a spoon to take samples in the pot for observation, and flexibly master the amount and speed of water addition according to the situation. After adding water, when the colloidal particles begin to gather, slow stirring is started, and the temperature is raised to 75 ℃. When the liquid level shows obvious oil path, stop stirring, and stand for 3-4 hours, 4-5 hours in winter. Until the separation of hydrated oil foot and grease is qualified, drain the oil foot to get degumming oil and enter the next procedure.

Deacidification: oil deacidification is mainly to remove free fatty acids in crude oil, as well as a small amount of gum, pigment and trace metal substances in oil. Deacidification is one of the important factors that directly affect the yield and quality of refined oil. The most widely used method in industrial production is alkali refining deacidification. Put the cleaning oil pump into the pot and stir evenly to make the oil temperature rise to 60 ℃. At the same time, carry out rapid stirring at the speed of 60 rpm, spray the measured lye into the oil evenly, and continue to stir quickly to make it fully mixed with the oil. Then, the stirring speed was changed to slow speed, and the rotation speed was 30 rpm. At the same time, raise the temperature to 75 ℃ until the oil and soap particles are obviously separated and easy to precipitate. Let it stand for 3 hours. When the oil temperature drops to 60 ℃, start to filter and enter the next procedure.

Decolorization: the color of oil and some other impurities can reach the product quality standard only after decolorization. At the same time, it provides more favorable conditions for deodorization and refining. Decolorization should meet the final color requirement of the product; Remove the relevant pigment and metal amount; Further remove the residual trace saponin, phospholipids and other colloidal impurities and some odor substances in the oil; Removal of polycyclic aromatic hydrocarbons and pesticide residues; Reduce the peroxide value of oil. Generally, activated carbon is used. The decolorized oil is sucked into the decolorizing pot from the oil storage tank by vacuum, and heated to 90 ℃ in vacuum. The air and water in the oil are removed. Then add the activated carbon (the amount of activated carbon is generally between 1-5% of the oil weight according to the color standard of decolorization), under the condition of full stirring in vacuum, contact the oil with the agent for about 30 minutes, cool it to 70 ℃, pump it into the filter, remove the activated carbon, and get the decolorized oil.

Deodorization: the purpose of oil deodorization is to improve the stability of oil quality. First, vacuum the deodorization pot. When the vacuum degree reaches a certain value, open the oil inlet valve, use the vacuum to suck the decolorized oil into the deodorization pot, raise the temperature in the pot to 190 ℃, and then pull the vacuum system. The deodorization time reaches 30 minutes before the oil deodorization. After the oil deodorization is completed, open the cooling valve and pump out the deodorized oil. The vacuum gas is cooled by the condenser, and the water enters the water seal pool to form circulating water.

Moringa oleifera seed oil press machine

Moringa oleifera seed oil press machine