Animal oil, namely animal fat, is the fat of animals. Animal oil for human consumption generally comes from pigs, cattle, sheep, fish and so on, which can be used to process food. The process of animal oil is generally divided into rough refining (crude processing equipment) and refining (edible grade).

The working principle of oil refining boiler is to use high temperature (the actual operating temperature is about 250 ℃). The small heating generally uses direct coal or fuel, and the slightly larger one generally uses heat conduction oil furnace for heating. The heat conduction oil furnace heats rapidly, evenly and at constant temperature. According to the volume, it can be divided into 0.5T, 1.0T, 1.2t, 1.5T, 2.0T, 2.5t, 3.0T and 4.0t.

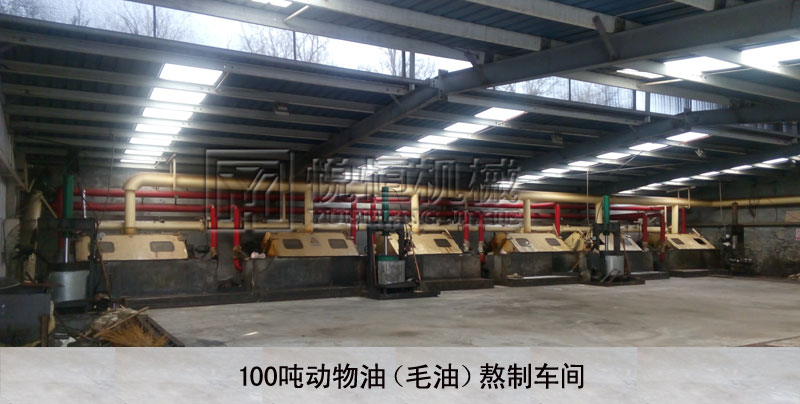

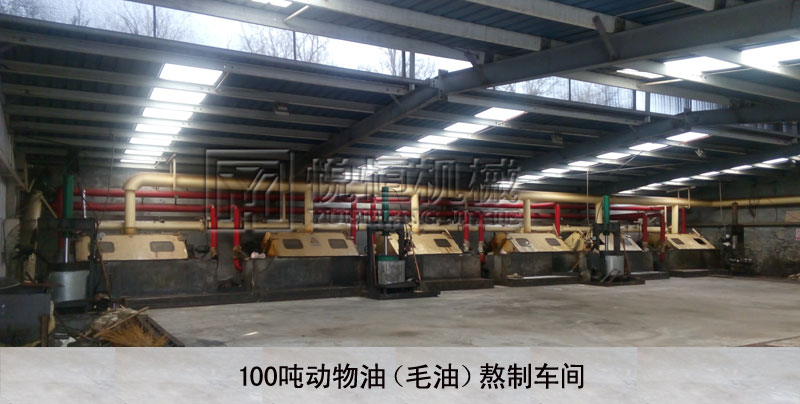

Complete equipment for animal oil refining

传统式炼油锅

立式负压炼油锅

立式负压炼油锅

卧式负压炼油锅

The whole set of equipment process of oil boiling under negative pressure:

The commonly used methods of crude extraction of animal fat are direct heating and steaming. At present, cooking method is mainly used in large-scale industrial production. The main advantages of cooking method for extracting animal oil are low cost, simple operation and no chemical reagent added. The extracted oil has higher safety.

Working principle: under the condition of pressure, add water vapor and heat to release oil from adipose tissue cells.

Main features: the product has light color, soft flavor and low free fatty acid content.

Technological process: raw material → dressing → rough cutting → washing → grinding → cooking → centrifugal impurity removal → precipitation → crude oil

First of all, select suitable oil raw materials, and then trim to remove blood clots, muscles, broken bones, fascia, lymph and other non adipose tissues, so as to avoid producing burnt smell or animal glue during cooking and emulsifying the oil.

Cut the finished raw materials into small pieces, then wash them to remove the surface dirt and odor, and drain them. They can be operated at 10 ~ 15 ℃ to prevent the deterioration of raw materials, increase the hardness and facilitate the grinding. Mincing raw materials with mincing machine is convenient for fat to escape and smelting time to be shortened.

Put the raw materials into the pressure tank, add steam cooking, denaturate the protein, destroy the adipose tissue cells, and make the fat flow out. Then the impurities are separated by centrifugation, and the crude oil is obtained after precipitation.

Animal oil refining equipment

In the process of crude extraction of animal fat, if properly treated, the obtained oil products can be used without further treatment. However, in production practice, due to a series of reasons such as blood stains left in tuzhai, the acid value of the obtained products is too high or there are impurities such as collagen. Therefore, these animal oils need to be further refined when they are consumed. There are degumming, deacidification, decolorization, deodorization and other steps in the refining of edible animal fat.

Process Description:

Degumming: the purpose of degumming is to remove colloidal impurities in crude oil, mainly some protein, phospholipid and mucinous substances. At present, the main method is hydration degumming.

Decolorization: the purpose of decolorization is to remove the pigment components in oil. Decolorization is achieved by adsorption decolorization method, which is completed by adding activated clay. A small amount of activated carbon can also be added. They can absorb pigment and some oil degradation products.

Deacidification: due to the high acid value of animal fat after boiling, it does not meet the health standard of animal fat, so deacidification treatment is needed. Physical deacidification by steam distillation is used in animal oil refining equipment.

Deodorization: deodorization is to remove the decomposition products of pollutants and raw protein mixed with the outside in the process of processing, and remove the aldehydes, ketones, low-grade acids, peroxides and other odor substances produced by the oxidation and rancidity of oil. The process is completed in the combined deacidification and deodorization tower together with the deacidification process.

Process flow: crude oil → hydration degumming → water washing → drying → dry degumming → decolorization → filtration → deoxidization → heat exchange → heating → physical deacidification → delayed decolorization → heating → deodorization → heat exchange → cooling → product oil

Complete equipment for animal fat packaging

Technological process: animal oil → heating → filtering → blending → milk pump → plunger pump → quenching I (precooling crystallization) → quenching II (cryogenic crystallization) → kneading and refining → discharging → packaging → coding → packaging → aging → normal temperature storage

Description of working process: animal oil is heated by steam and filtered, and then blended into other oil products to form a mixture. When the quick cooling kneader is working, the refrigeration system will send the liquid refrigerant into the interlayer of the quench cylinder I and II, and the mixture will enter the quench cylinder I and II through the milk pump and plunger pump (nitrogen is mixed during nitrogen charging). The power is reduced by the belt drive of the motor, and the hollow scraper shaft is driven to rotate through the jaw type coupling. Under the action of centrifugal force (hot water can prevent the scraper from unfolding), the scraper on the scraper shaft moves close to the inner wall of quench cylinder I and II for rotation. The feed liquid entering quench cylinder I and II from the feed port exchanges heat with the refrigerant outside the cylinder, transfers its own heat to the refrigerant (divided into precooling crystallization and cryogenic crystallization), and then is scraped off. The scraped oil semi-finished product goes into the kneading cylinder with a lot of agitation. Under the fierce agitation of the stirring rod, it is fully stirred and mixed& mdash; Kneading. Because the material liquid is continuously pressed into the barrel by the plunger pump, the pressure is applied to the material liquid in the barrel. Under the action of this pressure, the oil kneaded by stirring and scraping is continuously squeezed to the outlet, and the pressure of the adjustable expansion valve spring is overcome, so that the expansion valve is opened, the pressure drops suddenly, and the nitrogen bubble in the oil (when filled with nitrogen) expands, which makes the product loose. In this way, the organization is fine and pure, and has a certain luster Oil products with good plasticity and ductility are produced. Then filling, coding and packing are carried out. In order to further promote the ideal & beta; ' The formation and stability of crystal form. Only in this way can we get satisfactory and stable ideal products.

Product Description: according to the customer's demand for different conditions, such as the type of animal oil, daily processing capacity, oil standard and so on, the product is processed and customized, with different specifications, number of refining tanks and product prices.

Can undertake: 1-500 tons of lard, butter, mutton, chicken and duck oil, fox oil and other production line equipment

Product advantages: through dephosphorization, decolorization, deacidification, deodorization and other processes, the crude oil can reach the national standard oil quality standard. After refining, the refined product oil has clear color, no mucus, no deterioration and no peculiar smell after long-term storage.