Generally speaking, waste clay is activated clay sludge, which is used after decolorization and filtration of waste oil!

In the oil refining process, activated clay, which accounts for 2% ~ 3% of the oil weight, is usually used. After decolorization, the clay loses its activity and becomes waste clay, which is a large amount of solid waste.

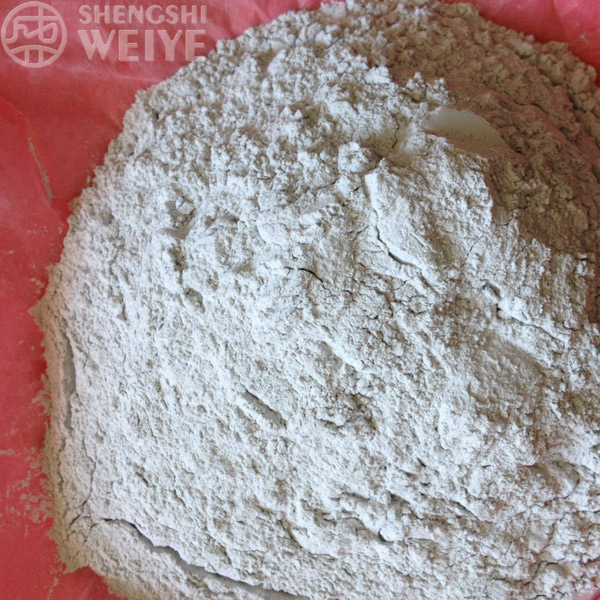

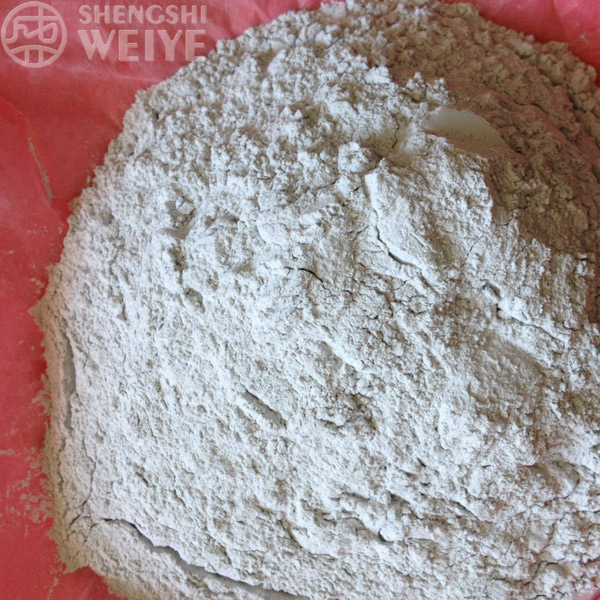

Activated clay is an adsorbent made of clay (mainly bentonite) as raw material, inorganic acidification treatment, water rinsing and drying. It has the appearance of milky white powder, odorless, tasteless, non-toxic, strong adsorption performance, and can absorb colored substances and organic substances.

It can be widely used in animal and vegetable oil refining, decolorization and purification, removing harmful pigments, phospholipids, saponins, gossypic acid from oil, making it a high-grade edible oil.

In petroleum industry, it is used for refining, decolorization and purification of petroleum, oil paraffin, wax oil, kerosene and other minerals, as well as petroleum cracking.

In food industry, it is used as clarifier of wine and candy juice, stabilization of beer, saccharification, purification of sugar juice, etc.

In chemical industry, it is used as catalyst, filler, desiccant, adsorbent and flocculant for wastewater treatment.

In terms of national defense, medicine and health, it can be made into Anti chemical drugs and antidotes.

With the development of society and science, the application of activated clay is more and more widely.

Properties of bleached soil

1. It has strong adsorption capacity, high decolorization rate, low oil carrying rate, fast filtration speed and less addition;

2. It can effectively remove the total phospholipids, soap and trace metal ions of oil, and can be used as a natural antioxidant;

3. It can remove aflatoxin, pesticide residues and other toxins and odor substances in oil;

4. After decolorization, the acid value of the oil does not rise, the color does not return, the oil is clear and transparent, the quality is stable, and the shelf life is long.

5. It is especially suitable for refining production of mineral oil, vegetable oil and animal oil.

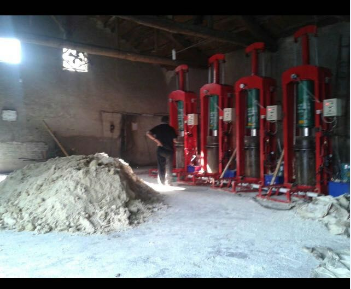

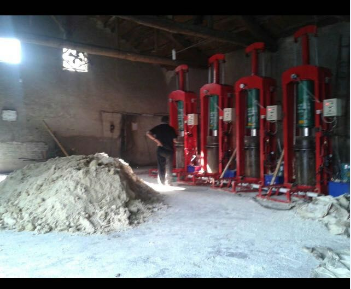

1. The machine is mainly composed of frame, oil cylinder, hydraulic station, manual reversing valve, oil barrel, tray and electrical control parts.

2. Working principle: according to the principle of hydrostatic pressure transmission, this machine uses hydraulic oil as pressure transmission medium to squeeze oil and then extract oil. It is a closed loop system composed of hydraulic system and oil press body.